- Home

- /

- Scrap shears

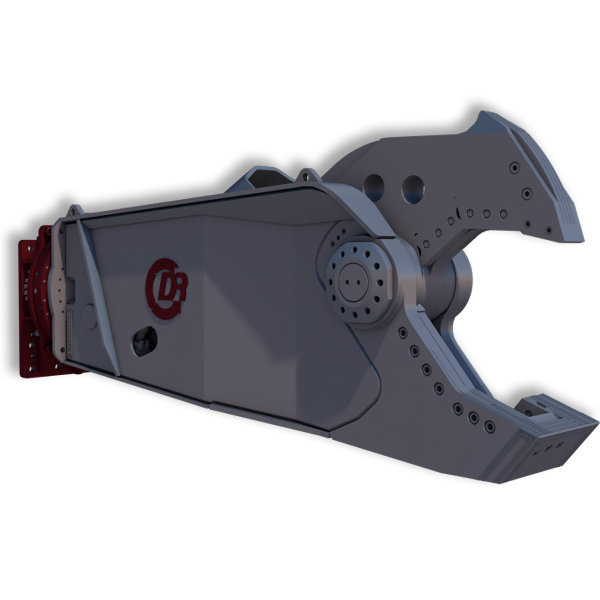

Scrap shears – DXS

The first type in our portfolio of scrap shears are the DXS scrap shears.

The DXS scrap shears have been developed to bring a shear ,with top performance, to the market.

Thanks to the DemaPower 2.0 cylinder in the DXS, it delivers 25% more performance and as a result the DXS scrap shears have extremely fast cycle times. As a result, the scrap shears deliver the performance of shears one or two sizes larger.

The shears also have a number of other features. First, the shears have filters in the rotation circuit. As a result, no dirt gets into the machine and also not into the scrap shear. The DemaSafety system is also incorporated in the DXS scrap shear. This system ensures that the cylinder is protected against excessive pressure. Furthermore, the cylinder is inverted in the housing. This makes it completely protected against dirt from the outside. Also the DXS scrap shears have an offset apex jaw design. This design forces the material into the jaws and causes it to begin to cut during the compression of the material.

Would you like to read more about the DXS scrap shear? Then click on the button below.

€0.00Buy Now

€0.00Buy Now

Scrap shears – DRS

The second type within our portfolio of scrap shears are the DRS scrap shears.

The DRS scrap shear is the original Demarec scrap shear. These scrap shears were first developed by us.

In contrast to the DXS scrap shears, the DRS shears have a standard cylinder. Despite the standard cylinder, the DRS scrap shears also deliver high power. Furthermore, these shears deliver a high speed and a good weight ratio.

The DRS do have, just like the DXS, the Demarec DNA. Think of filters in rotation and two rotary motors for high rotational force. Furthermore, the cylinder is completely protected in the housing and therefore no debris can get on the cylinder. The large jaw opening also makes cutting profiles easy. This makes the DRS scrap shear the ideal shear for daily use on the scrap and recycling site.

MQP with steel-jaw

The third option in our portfolio of scrap shears is the Multi-Quick Processor. The MQP is originally not just a scrap shear. After all, this piece of equipment is known for being able to change jaws. That’s why the MQP is available in four different types with six to eight jaw sets. The jaw that is used when cutting steel is the so-called Steel-jaw. This jaw ensures, as it were, that the MQP becomes a scrap shear. But there are also jaws for cutting concrete structures with reinforcing bars, wood and for cutting steel structures and tanks. As a result, the jaws fit perfectly in all harsh conditions during demolition and recycling.

In all cases, the emphasis is on efficiency and sustainability.

Moreover, and perhaps more importantly a Demarec MQP has an extra performance of up to 20% compared to any other competing brand. In other words: more profit thanks to more power and more speed.

€0.00Buy Now

€0.00Buy Now

Multi-shear with Steel-jaw

Finally, the last type of scrap shear in our portfolio is the DMS multi-shear.

However, the DMS scrap shear is for smaller machines. The DMS scrap shear is suitable for machines from 3 to 9 tons.

Like the Multi-Quick Processor, the DMS consists of different types. However, the DMS series consists of three jaw types. The steel jaw is one of these. Furthermore, the DMS is available with a Combi-jaw or with a Cable-jaw.

The DMS is by far the smallest scrap shear in our range. However, this doesn’t make him any less strong.

The DMS scrap shear delivers good cutting performance for its size. Furthermore, it is a multifunctional shear thanks to the mechanical exchange system. The DMS also has the necessary Demarec DNA and is therefore the ideal scrap shear for the smaller machine.

So are you looking for a small and strong scrap shear? Then the DMS with S-jaw is the perfect shear!